Hydraulic systems are integral to numerous industrial applications, from construction machinery to manufacturing processes. The efficiency and reliability of these systems are crucial for maintaining productivity and ensuring smooth operations. One often overlooked aspect that plays a significant role in achieving optimal performance is the quality of hydraulic hoses and fittings. In this blog, we explore how investing in high-quality hydraulic hoses can enhance the efficiency of hydraulic systems.

The Importance of Hydraulic Hoses and Fittings

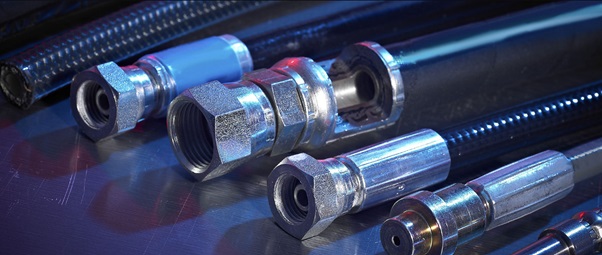

Hydraulic hoses are essential components of hydraulic systems, responsible for transmitting fluid between various parts of the system. Their primary function is to maintain the pressure and flow of hydraulic fluid, which powers the system’s components. The quality of these components directly impacts the system’s efficiency, reliability, and overall performance.

High-quality hoses and fittings are designed to withstand the demanding conditions of hydraulic systems, including high pressure, extreme temperatures, and exposure to harsh environments. They ensure that hydraulic fluid flows smoothly and consistently, which is crucial for maintaining the system’s performance and preventing potential failures.

Enhancing System Efficiency with Quality Components

Investing in high-quality hoses and fittings can lead to significant improvements in system efficiency. One of the key benefits is the reduction of energy losses. High-quality components are engineered to provide minimal resistance to fluid flow, which helps in maintaining optimal pressure levels throughout the system. This efficiency in fluid transfer reduces the energy required to operate the system, leading to lower energy consumption and operational costs.

Furthermore, quality hydraulic hoses and fittings are designed to minimise leaks. Leaks in hydraulic systems can lead to a loss of fluid, decreased system pressure, and reduced performance. High-quality components are manufactured with precision and tested rigorously to ensure that they provide a secure and leak-proof connection. This reliability helps in maintaining consistent system pressure and optimising overall efficiency.

Durability and Reliability: Key Benefits

Durability is another critical advantage of high-quality hoses and fittings. Hydraulic systems often operate in harsh conditions, including high temperatures, abrasive environments, and exposure to chemicals. Components that are not designed to withstand these conditions can deteriorate quickly, leading to frequent replacements and downtime.

High-quality hoses and fittings are made from materials that are resistant to wear and tear, ensuring long-term durability. For instance, premium hoses often feature reinforced layers that provide extra strength and resistance to abrasion. Similarly, high-quality fittings are crafted from robust materials that can endure high pressure and temperature fluctuations. By choosing durable components, businesses can minimise maintenance needs and reduce the risk of unexpected failures.

Preventing Downtime and Reducing Maintenance Costs

The reliability of hydraulic systems is closely tied to the quality of their components. High-quality hoses and fittings contribute to the overall reliability of the system, which helps in preventing unexpected downtime. System failures due to substandard components can lead to costly repairs and production stoppages.

By investing in superior hoses and fittings, businesses can significantly reduce maintenance costs. Quality components are less prone to failure, which means fewer repairs and replacements are needed over time. This not only lowers maintenance expenses but also contributes to uninterrupted operations, enhancing productivity and profitability.

Choosing the Right Hydraulic Hoses and Fittings

Selecting the appropriate hoses and fittings for a specific application is crucial for maximising efficiency. Several factors need to be considered, including the operating pressure, fluid type, temperature range, and environmental conditions. High-quality components are designed to meet these specific requirements, ensuring optimal performance and compatibility.

When choosing hoses and fittings, it is essential to work with reputable suppliers who offer products that meet industry standards. Look for components that are certified and tested for quality to ensure that they can handle the demands of your hydraulic system. Additionally, consulting with experts or engineers can provide valuable insights into selecting the right components for your specific needs.

Conclusion

High-quality hydraulic hoses and fittings are vital for maximising efficiency in hydraulic systems. They enhance system performance by reducing energy losses, minimising leaks, and providing durability and reliability. Investing in superior components helps in preventing downtime, reducing maintenance costs, and ensuring the smooth operation of hydraulic systems.

By prioritising the quality of hoses and fittings, businesses can achieve better efficiency, lower operational costs, and improved overall performance. As hydraulic systems continue to play a crucial role in various industries, the importance of selecting and maintaining high-quality components cannot be overstated. Ensuring that your hydraulic system is equipped with the best possible hoses and fittings is a key step towards achieving optimal efficiency and reliability.