In today’s modern age, machines are the best friend of many manufacturers and factories. Without them, these companies may not be able to meet the needs of the world. Industrial machines and tools, like a positioning sensor and rotary encoder, ensure a steady supply of goods in the market by producing products faster and in high volumes. However, a broken machine severely affects the production of a factory, hence impacting the supply chain.

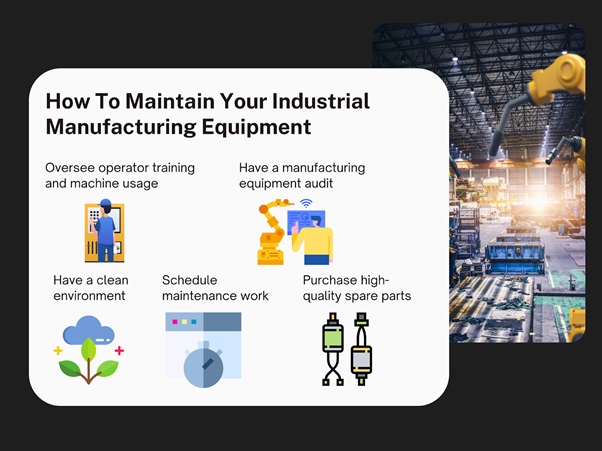

Here are the ways to maintain and extend the lifespan of your industrial equipment and tools:

1. Oversee operator training and machine usage

Machine damage starts from the improper use of machines. Equipment and tools, like a lidar sensor and industrial switch, wear out quickly because of mishandling. The entrepreneurs must conduct machine operator training and refreshers regularly and assess the practices of the operators. Engineers and trainers can correct the misuse of machines through these activities.

2. Have a manufacturing equipment audit

A manufacturing equipment audit contains essential information about the machines, like the frequency of inspection needed for tools and parts that need replacements, and schedule a basic repair and temporary shutdown of the equipment.

3. Have a clean environment

Contaminants and dirt buildups impair the performance of machines and tools, like a positioning sensor and rotary encoder. Apart from it being unsanitary, it can also cause accidents, like fire breakouts.

4. Schedule maintenance work

Periodic checks help determine and prevent future problems with your machine. It is much better to partner up with repair and maintenance services with in-depth knowledge about the equipment. More than the physical state of the tools, they can also pinpoint unnoticeable changes in your machine.

5. Purchase high-quality spare parts

If you experience a sudden machine breakdown, having high-quality spare parts for immediate troubleshooting will save you time and money. It is better to have a spare lidar sensor and industrial switch on hand.

Save money from downtime, repair cost, and profit loss by maintaining your industrial machine.

Pepperl+Fuchs Asia provides superior automation tools and equipment for your factory. Visit Pepperl+Fuchs Asia today.