Etching and engraving, ancient crafts with a rich history, have transformed significantly through innovative technologies. This comprehensive article will trace the journey from traditional craftsmanship to the precision offered by laser technology in etching and engraving. It will focus on the impressive capabilities of laser etching on aluminium and stainless steel, marking a new era of precision and durability in these arts.

Traditional Etching and Engraving Techniques

The Craftsmanship of the Past

Traditional etching and engraving were masterful works carried out by skilled artisans using tools like chisels, burins, and chemical baths. These craftsmen etched intricate designs and text onto materials like wood, metal, and glass, creating exquisite art pieces.

Limitations of Traditional Methods

While these traditional techniques showcased exceptional artistry, they had their limitations. Precision relied on the artisan’s skill, the process was labor-intensive and time-consuming, and engravings were often susceptible to wear and tear over time.

Laser Precision in Etching and Engraving

The Advent of Laser Technology

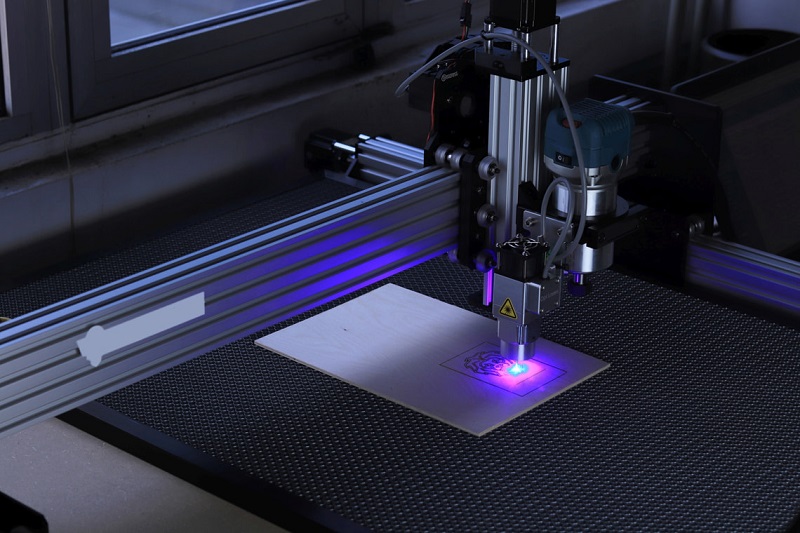

The introduction of laser technology in etching and engraving brought a paradigm shift. Laser precision utilises a focused beam of light to accurately etch or engrave materials. This technology allows for creating highly detailed designs and text on materials like aluminium and stainless steel.

The Power of Laser Etching on Aluminium

Laser etching on aluminium has gained popularity due to its precision and durability. The laser beam can create intricate patterns, logos, and text on aluminium surfaces, ensuring that the engravings withstand harsh environmental conditions and remain clear and legible.

Stainless Steel Engraving with Laser Precision

Stainless steel engraving using laser technology offers unparalleled precision and permanence. The laser beam’s accuracy allows for detailed designs and markings on stainless steel, making it a preferred choice for industries where durability and resistance to corrosion are essential.

Advantages of Laser Precision

Precision and Detail

Laser precision in etching and engraving offers an unmatched level of detail. Complex designs, fine text, and intricate patterns can be etched or engraved with pinpoint accuracy, allowing for the creation of highly personalised and visually appealing products.

Durability and Permanence

Engravings created with laser precision are highly durable and resistant to wear and tear. They maintain their clarity and legibility, even in harsh environmental conditions, making them ideal for a multitude of applications, from industrial components to personalised gifts.

Versatility and Adaptability

Laser precision technology boasts remarkable versatility and adaptability, capable of accommodating a broad spectrum of materials like metals, plastics, and glass. This advanced technology extends an enticing invitation to both businesses and individuals, granting them the freedom to effortlessly personalise an array of items, signage, and promotional materials.

Conclusion

The journey from traditional etching and engraving to laser precision has revolutionised the field. Laser etching and engraving exemplify the potential of this technology, delivering unrivaled precision, longevity, and flexibility. Whether for industrial applications or personalised embellishments, laser precision has ushered in a new era of etching and engraving, redefining the horisons of creativity and innovation.

Learn more about laser etching and engraving by checking out Artcom Fabrication. It is a company based in Western Australia that specialises in designing as well as manufacturing cost-effective and unique solutions for signage, etching, wide format printing, 3D printing, engraving, fabrication, and CNC routing services.